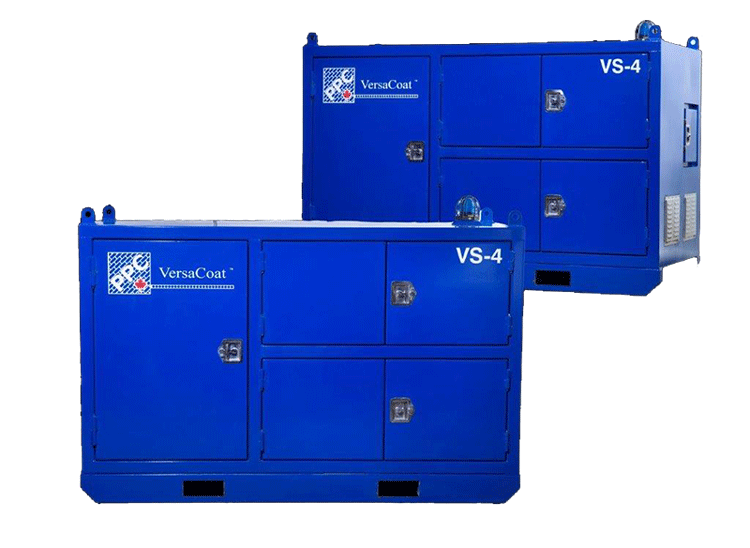

VersaCoat System

Paragon FusionClad

Precision Controls

VersaCoat system components include on-board compressor (including air drier and oil separator), generator, microwave oven, and heated, temperature controlled storage bunks for spray cartridges.

MQAP requirements

PPC’s fully integrated VersaCoat system training includes cartridge spray MQAP application requirements, VersaCoat system operation, and CSA and client specification requirements.

GPS Controls

Onboard heater bunk tightly controls cartridge temperature and is monitored with remote beacon controlled technology. The GPS traceable control allows heat system monitoring from anywhere via internet. Cartridge temperature is verified with heat guns.

Time & Cost Efficient

Extremely reliable equipment minimizes potential for downtime compared to conventional mobile plural spray systems – no high pressure pumps, valves and other more complicated heating equipment to maintain.

VersaCoat Advantages

VersaCoat Equipment is easy to operate. Operators can be trained in a relatively short period of time compared to a plural spray truck.

MQAP Application Requirements

PPC’s fully integrated VersaCoat system training includes cartridge spray MQAP application requirements, VersaCoat system operation, and CSA and client specification requirements.

Easy to Operate

VersaCoat Equipment is easy to operate. Operators can be trained in a relatively short period of time compared to a plural spray truck.

Built-in System Controls

VersaCoat system components include on-board compressor (including air drier and oil separator), generator, microwave oven, and heated, temperature controlled storage bunks for spray cartridges.

HSE Advantages

VersaCoat system mounted on a 4X4 flat deck crew truck and is safer to operate with a smaller safety footprint than a plural spray truck.

Less Environmental Impact

Quiet to operate, negligible potential for environmental spills, low fuel consumption, less coating material waste and no thinner flushing required and thinner waste

Lower Pressure

Lower pressure VersaCoat system is safer to operate than high pressure plural systems. 100 PSI as opposed to several thousand PSI plural spray trucks.

Versacoat Plural Coating System

VersaCoat System

Up to 50% less manpower and product required for VersaCoat system compared to conventional plural component spray trucks. Faster to heat to spray time compared to conventional plural spray units (just minutes vs. 4 – 6 hours). Improved coating application productivity and quality over hand applied (brush and roll) coating

Continuous on/off finesse spraying

Excellent for difficult shapes because of the moderate spray pressure and the continuous on/off finesse spraying capability of the system. 90 degree spray tips allow access to difficult to spray locations caused by existing obstructions. Ditch excavation under the pipe can be reduced. Feed hose lengths up to 250’ – 300’ for difficult to reach spray applications.

Continuous on/off finesse spraying

Excellent for difficult shapes because of the moderate spray pressure and the continuous on/off finesse spraying capability of the system. 90 degree spray tips allow access to difficult to spray locations caused by existing obstructions. Ditch excavation under the pipe can be reduced. Feed hose lengths up to 250’ – 300’ for difficult to reach spray applications.

Reliable Equipment and Precision Application

VersaCoat system components include on-board compressor (including air drier and oil separator), generator, microwave oven, and heated, temperature controlled storage bunks for spray cartridges. Extremely reliable equipment minimizes potential for downtime compared to conventional mobile plural spray systems – no high pressure pumps, valves and other more complicated heating equipment to maintain.